Erdyn is proud to share the launch of a comprehensive guide on Industry 4.0 and Food Safety, in collaboration with SSAFE, a prominent global non-profit membership organization committed to addressing emerging challenges that impact the safe production and distribution of food worldwide. SSAFE boasts a distinguished membership roster, featuring industry leaders such as Cargill, The Coca-Cola Company, Compass, Danone, Givaudan, Kellogg, Kerry, Mars, McDonald’s, Nestlé, and Tyson.

Erdyn played an active role in the development of this guide, which has been designed to assist food industry stakeholders throughout the entire supply chain in accelerating the adoption of cutting-edge technologies and maximizing the return on their technological investments.

In a world where innovation and technology continually shape industries, the food sector is no exception. The Fourth Industrial Revolution, known as Industry 4.0, is ushering in a new era of food safety, promising a revolution that can enhance quality and security in the food supply chain. This article is a guide aimed at food companies to harnessing the power of Industry 4.0 for a safer, more efficient, and ultimately more competitive food industry. Here are some key takeaways:

- Understanding Industry 4.0: Redefining the Future of Food Safety

Industry 4.0 is a fusion of groundbreaking technologies that blur the lines between the physical, digital, and biological worlds. From the Internet of Things (IoT) to artificial intelligence (AI), blockchain, advanced analytics, and more, Industry 4.0 promises a profound transformation of the food industry.

- The target audience of this paper is the following:

- Food companies of all sizes, across the supply chain, frontrunners and newcomers to Industry 4.0

- Food Safety and Quality Departments to better understand the Industry 4.0 benefits

- Top Management, supply chain / procurement, digital / IT departments to understand the benefits of integrating food safety in the digital strategy from the start.

- HR Departments to get a sense of which employees will be impacted.

- Suppliers of the food industry to develop digital solutions matching the interest of their customers

- Government agencies

- Certification / auditing organizations

- The Potential benefits of Industry 4.0 for Food Safety are:

- Strengthening traceability and transparency capabilities

- Providing process assurance through repeatable processes delivering products with consistent and predictable quality and food safety

- Allowing parametric release of products

- Bolstering predictive capabilities to enhance the resiliency of products and process.

- Supporting the continuous improvement of food quality and safety

These benefits are enabled by real-time monitoring of product and processes, connected data, risk-based modeling connected across the value chain, automation as well as the right mindset and right behavior.

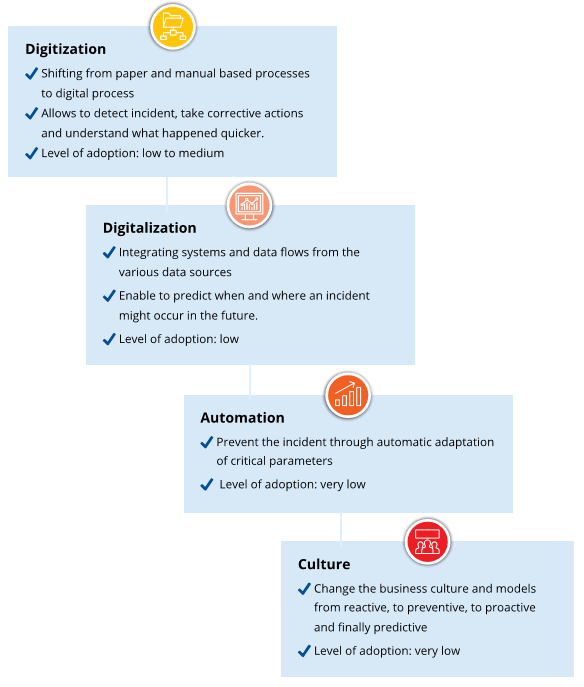

- The adoption of Industry 4.0 is in its infancy in the food industry. Currently, the food industry is embracing digitization. Predictive analytics is still in its infancy and is struggling with data integration, limiting the ability for food businesses to truly leverage its full potential. Automation to prevent incidents is applied only in a very localized way and rarely deployed to leverage data as an additional source of revenue.

- The following recommendations are key for effective Adoption

- Define a Unique Strategy: Develop a holistic strategy with a multidisciplinary team, emphasizing food safety as an investment for continuous improvement.

- Invest in Skills and Talents: Identify skill gaps and invest in upskilling the workforce. Foster a digital mindset and data-driven decision-making.

- Define Critical Pain Points: Prioritize technology adoption based on quantifiable business value. Select technologies that address multiple pain points for a higher return on investment.

- Think About Scaling Early: Anticipate data integration and scalability needs. Ensure data quality and communication network readiness.

- Collaborate Beyond Your Organization: Choose providers who offer collaborative, customized solutions and can help with data analysis. Engage with external stakeholders and customers to align with Industry 4.0 strategies.

- Implement Cybersecurity and Data Ownership Culture: Invest in data management solutions that secures the access rights to data and in traceability to mitigate cybersecurity by enabling fast root-cause analysis and selective recalls.

- Realizing the full potential of Industry 4.0 requires collaboration and strategic cross-industry initiatives:

- Need for harmonizing standards to allow interoperability at the company level and across the supply chain.

- Need for data ownership and business models to incentivize data sharing by food companies with health agencies and the entire food sector.

In conclusion, Industry 4.0 is not just a buzzword; it’s the future of food safety. By embracing innovation, fostering collaboration, and cultivating a culture of excellence, food companies can elevate their quality, safety, and competitiveness. The path to Industry 4.0 is paved with opportunities, and the time to embark on this transformative journey is now. Join the ranks of forward-thinking food industry leaders and take your food safety practices to new heights.

The guide is accessible here