Erdyn recently shared an article on a comprehensive guide on Industry 4.0 and Food Safety, written in collaboration with SSAFE, a prominent global non-profit membership organization. SSAFE boasts a distinguished membership roster, featuring industry leaders such as Cargill, The Coca-Cola Company, Compass, Danone, Givaudan, Kellogg, Kerry, Mars, McDonald’s, Nestlé, and Tyson.

Erdyn played an active role in the development of this guide, which has been designed to assist food industry stakeholders throughout the entire supply chain in accelerating the adoption of cutting-edge technologies and maximizing the return on their technological investments.

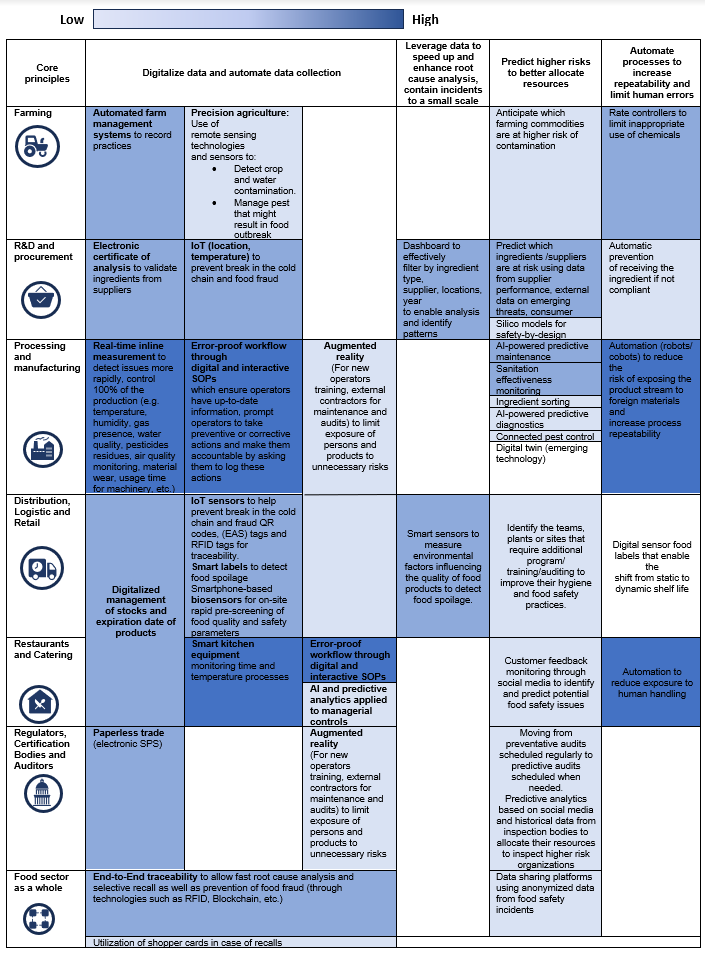

We wanted to share with you an overview of which Industry 4. 0 technologies are currently used for food safety and their relative adoption, from digital data collection, automated root cause analysis, risk prediction, and process automation for every link of the value chain.

The food industry has already well adopted some technologies (dark color) while others are still in the early stage of their adoption by the food industry (light color).

While Industry 4.0 technologies offer significant potential to transform industries, their adoption is still in an early stage overall compared to other industries. Many food industries and businesses are just beginning to explore the possibilities of these technologies. Despite a lot of news in 2019 the adoption of Industry 4.0 technologies was between 20% to 40% for the food and beverage industry while sectors such as oil and gas had an uptake over 80% and automotive of 45 to 60%. Therefore, there is an opportunity for the food sector to learn from these industries’ experience to transition more quickly towards Industry 4.0 technologies. The rapid pace of technological advancement suggests that Industry 4.0 adoption is likely to accelerate in the coming years.